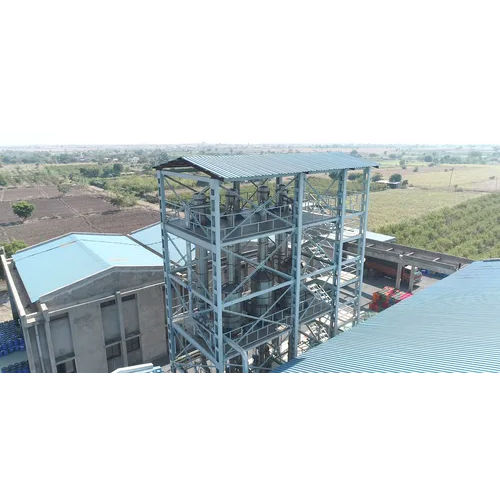

About Tomato Processing Plant

Tomato Processing Plant that proposed by us is engineered to be utilized for processing raw tomatoes and converting them into ketchup, sauce, puree, and powder. Most widely used in food processing industry, the plant is easy to install, simple to operate, highly efficient, and low in maintenance as it is engineered and developed by ingenious professionals with ultra-modern technology and using top of the line parts & components by following industry standards. In addition, the Tomato Processing Plant is available in varied sizes, capacities, specifications and models.

Advanced Tomato Processing TechnologyUtilizing both hot and cold break processes, our plant delivers high-quality tomato pulp, puree, juice, and ketchup. The design allows optimal retention of nutrition, color, and flavor in every output product. Efficient heating, mixing, and cooling systems operate reliably at temperatures up to 110C, ensuring consistent results.

Robust Construction and HygieneThe plant is constructed with premium stainless steel and food-grade contact parts for maximum durability and hygiene. Clean-In-Place (CIP) compatibility ensures thorough cleaning, reduces downtime, and maintains food safety standards. Customers can choose between continuous or batch production lines.

FAQs of Tomato Processing Plant:

Q: How is the tomato processing plant installed and commissioned?

A: Installation and commissioning of the plant are provided by our experienced technicians. We manage equipment setup, system integration, and provide operational training to ensure seamless start-up on site anywhere in India or for export projects.

Q: What types of tomato products can be produced using this plant?

A: The plant is suitable for manufacturing tomato pulp, puree, juice, ketchup, and sauce. It efficiently handles fresh tomatoes and adapts to different processing applications as required by the client.

Q: What are the main processes involved in tomato product manufacturing?

A: The processing line utilizes hot/cold break technology for extracting pulp, homogenizing, refining, evaporating, and pasteurizing. Temperature control up to 110C allows for nutritional retention and product consistency across paste, puree, and ketchup.

Q: Which utilities are required for operating the tomato processing facility?

A: To run the plant efficiently, utilities such as water, electricity, steam, and air are required. These are essential for powering, heating, cleaning, and operating various systems within the production line.

Q: Can the processing plant be customized for specific requirements?

A: Yes, customization is available to suit particular production capacities, output products, and workflow needs. Our team works closely with clients to implement solutions that fit unique process parameters.

Q: How does the CIP cleaning system benefit plant operation and hygiene?

A: The Clean-In-Place (CIP) system allows for thorough automated cleaning of equipment without dismantling, ensuring hygiene and reducing manual labor. This not only maintains food safety but also minimizes production downtime.