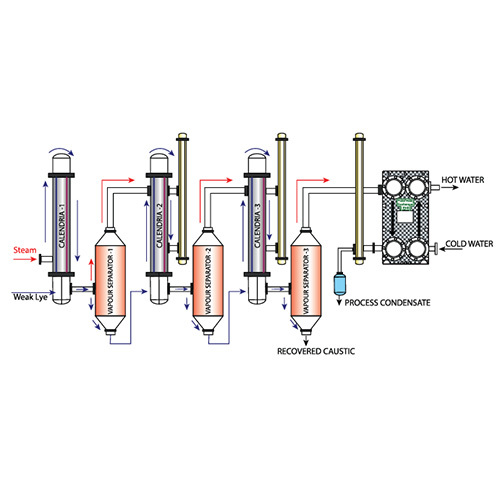

About Caustic Recovery Plant

Caustic Recovery Plant is a multiple effect evaporation plant designed for re-concentrating the weak lye in the heat exchanger. This is designed to weak caustic lye from 40 to 50 gmfitr to 250 to 450 gmIltr in dry-in-wet or wet-in-wet mercerizing. It is widely used in textile industry for separating the wash liquor from mercerizer. The condensate is used for pre-washing. In addition, the caustic soda can also be reused in the mercerizing process.

Specification

- Brand : CentPro

- Feed Flow Rate (cubic-meter/day) : 500 m3/day

- Automation Grade : Automatic

- Water Pump Power : 1.5 kW

- Air Blower Power (kW) : 0.5 kW

- Material : Mild Steel

The Caustic Recovery Plant is meticulously designed to withstand demanding industrial conditions. With multiple material options and a robust construction, the system achieves significant chemical recovery, cost savings, and compliance with environmental discharge regulations.

Turnkey Solutions Tailored to Your NeedsFrom site survey to post-installation support, our turnkey approach ensures every Caustic Recovery Plant meets your specific process requirements. Whether you need a fully customized setup or a standardized solution, we guide you through every project phase.

Automation and Safety PrioritizedOur plants offer both PLC-based automation and manual control, ensuring operational safety and flexibility. Integrated safety features and precise process monitoring enable trouble-free operation and minimal maintenance requirements.

FAQs of Caustic Recovery Plant:

Q: How does the Caustic Recovery Plant work?

A: The plant efficiently recovers caustic soda from spent wash using a combination of steam heating, controlled pressure, and temperature. This process typically involves evaporation and condensation, separating caustic soda for reuse while reducing effluent load.

Q: What materials of construction are available for the Caustic Recovery Plant?

A: We offer construction in Stainless Steel, Alloy Steel, or FRP, selected according to the corrosive nature of your process fluids and operational demands. Our team helps determine the best material based on your industry and specific requirements.

Q: When is it beneficial to install a Caustic Recovery Plant?

A: Installation is especially advantageous when your facility regularly generates waste streams containing caustic soda, such as in textile, dyeing, pulp & paper, or chemical manufacturing. Recovering and reusing caustic leads to substantial cost savings and environmental benefits.

Q: Where can the Caustic Recovery Plant be installed?

A: The plant can be installed at any industrial site across India within the specified industries. We provide comprehensive installation services, ensuring seamless integration within your existing operations.

Q: What are the key benefits of using your Caustic Recovery Plant?

A: Benefits include reduced raw material costs by reclaiming caustic soda, lower effluent discharge volumes, compliance with environmental standards, and enhanced process sustainability. Automation options further improve operational efficiency.

Q: How is the process controlled and what power source does it utilize?

A: Our plants are operated via an advanced PLC-based system for automation or can be manually controlled, according to your preference. The entire system is powered by electricity, ensuring consistent and reliable operation.

Q: Is the plant available for turnkey projects and does it include installation support?

A: Yes, we deliver turnkey or fully customized Caustic Recovery Plants with full installation and commissioning support, allowing quick start-up and optimized performance tailored to your project needs.